Description

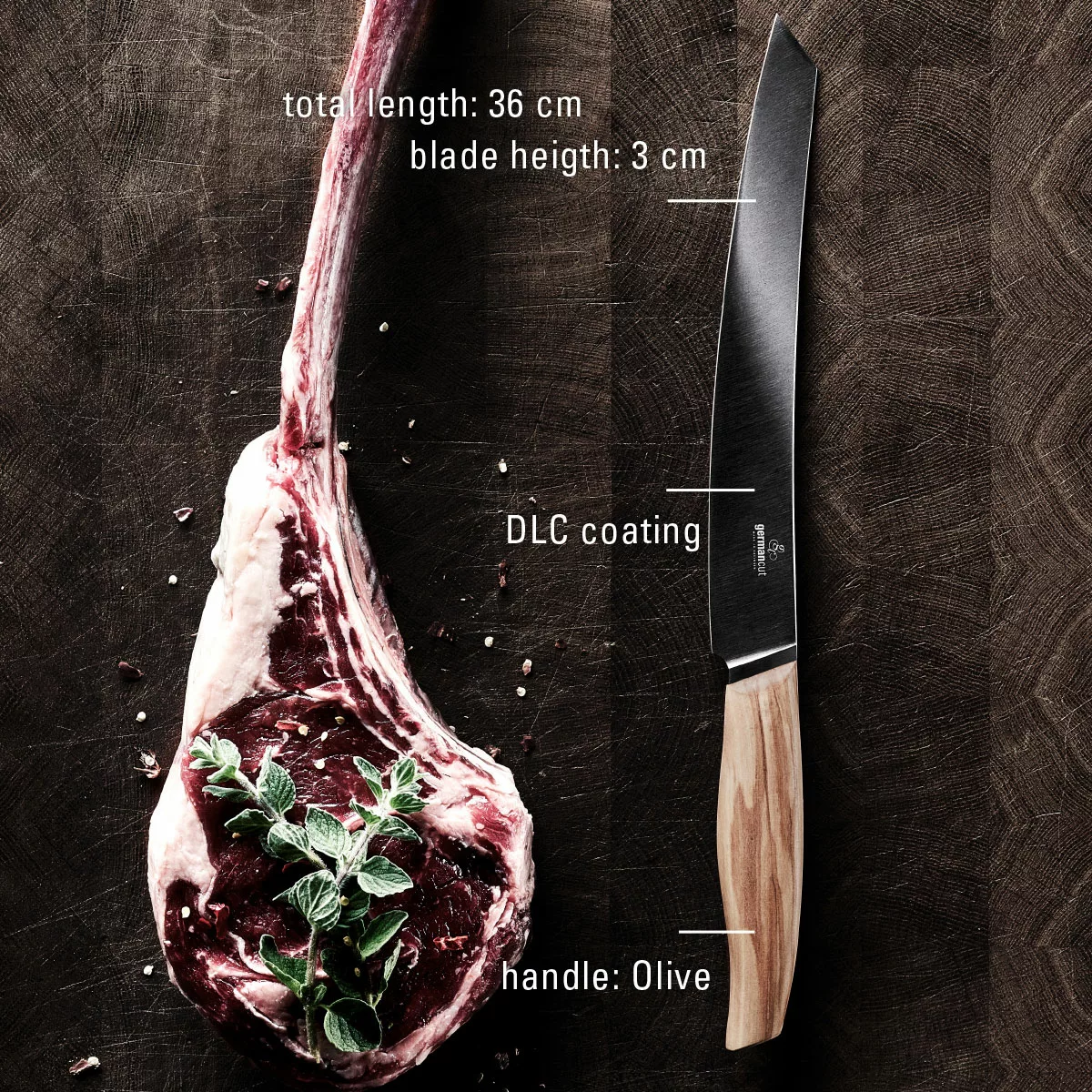

The blade is hardened to 59 Rockwell and precision ground and sharpened on both sides. Its high-quality DLC (Diamond like Carbon) coating seals the blade with non-stick effect and allows the very sharp cutting edge to glide even more effortlessly through all foods to be processed. The handle convinces with its excellent ergonomics and is made of noble bog oak.

IMPORTANT NOTE: As bog oak is a natural product, the discolouration varies from brownish to black.

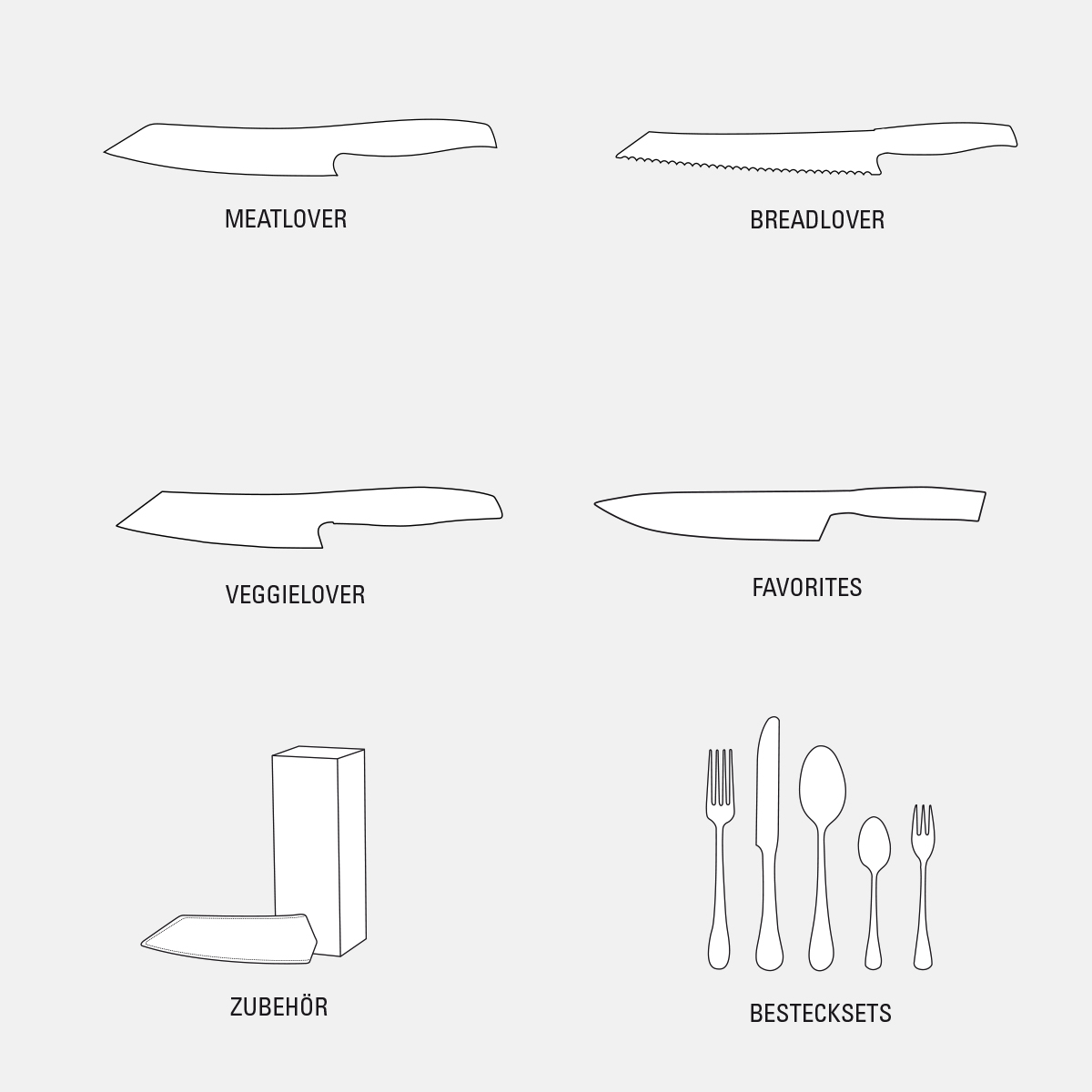

The illustrations are only exemplary.

FAQ

- Question: What is bog oak, exactly?

Bog oak wood is obtained from oak trucks that have been refined by nature itself over time – it is therefore not a separate type of wood but rather very old and valuable oak wood. The oak trunks have survived for thousands of years in wild bogs before they were discovered and are now worked to form our ergonomic knife handles after a slow and careful drying process.

While the oak trunks lie hidden deep in the bog for thousands of years, the wood becomes coloured and hardened. This reaction provides the characteristic properties of the wood which set it apart and make it so valuable. The bog oak gets its intense black colour through this storage in the bog and has this to thank for its particularly refined appearance.

- Question: What is a DLC coating?

The diamond-like carbon treatment (DLC for short) is a diamond-like carbon coating and numbers among the amorphous carbon materials. It has some of the unique and characteristic properties of diamonds. The DLC coating is applied to the blades in order to further optimise their properties – for particular resistance to wear and for outstanding frictional and non-stick properties.

In addition to the increased resistance to wear, the look also benefits from the wafer-thin carbon layer because the blade becomes an unmistakeable black as a result of the surface treatment. This wonderful black knife blade stands for top quality.

- Question: Why is Sandvik 12C27 steel the perfect blade steel?

Sandvik 12C27 is the best rounded knife steel from the traditional Swedish company Sandvik, which has been setting continuously new standards in the steel industry and steel production for more than 150 years. The special Sandvik 12C27 steel stands out with its high hardness and tremendous sharpness, as well as impressing with its exceptional toughness and its outstanding edge performance and corrosion resistance. It guarantees optimal cutting performance and give the knife blade unbeatable sharpness and performance.

- Question: What does HRC stand for?

HRC denotes the Rockwell hardness and is the unit of measurement used to define the hardness of knife steel.

A soft blade shows signs of wear more quickly than a hard one, the wafer-thin cutting edge stays sharp for longer and has outstanding durability thanks to higher hardness. For this reason the quality of a knife is significantly dependent on the hardness of the knife steel.

Good kitchen knives – Made in Germany – are generally in the 55 to 57 HRC range. Outstanding kitchen knives, including ours, can even reach 59 HRC – this hardness is achieved by knives made from Sandvik 12C27 steel.

Made in Germany // Available only while stocks last

blade length: 23 cm

blade thickness: 3 cm

total length: 36 cm

weight: 130 g

material: Sandvik steel 12C27 (59 Rockwell)

handle variant: bog oak